The same nature problem (the lack of the health drinking water in the sense of quality and quantity) happened municipalities of Arilje, Požega, Lučani, Čačak and Gornji Milanovac.

Because of that reason the municipalities agreed in the mid-80’s to start together with The Republic the construction of the original the water supply system “Rzav” in Arilje, as the final solution of the health drinking water supply problem for the municipalities of Arilje, Požega, Lučani, Čačak and Gornji Milanovac.

The base of the whole project of the water supply system “Rzav”. The river Rzav that runs trough Arilje where is situated the clearing water plant from the river bed of the above mentioned river.

After several years the river Rzav flow monitoring, it is found with a large reliability that the river Rzav flow is satisfactory and that the water from the river is of extraordinary quality as the consequence of the fact that river Rzav is formed from the water runoff from the land surface of 580 km2 from the mountain slopes of Zlatibor, Murtenica and northern slope of Mučanj, which are without a single industrial pollution and with undeveloped traffic.

According to all previous monitoring the clearing water factory was built in Arilje and since 14/06/1999 it has been supplying the municipalities of Arilje, Lučani, Požega, Čačak and Gornji Milanovac with health drinking water in the quality that is in accordance with the regulative standards and satisfactory quantity.

The concept of the water supply system “Rzav”

A general review

The concept of the water supply system “Rzav” is based on the adapted water economic solution of Rzav.

Regional water supply system “Rzav” supplies with water following towns: Arilje, Požega, Lučani, Čačak and Gornji Milanovac.

Basic elements of the system Rzav are: the accumulation at the profile Svračkovo, the water processing factory in Arilje and major water supply pipelines to the city storage tanks. Projected system capacity is 2300 l/s in the period up to the year 2030. The system realization is done in several stages to carry out the principle of the gradual financing.

The first stage includes the construction of the following objects:

* Accumulation “Arilje” with a dam at the profile Svračkovo. The preparations for the building of the accumulation in duration in sense of creation and revision of the project documentation. All research works has been done and State Ministry of Construction Commission revised the project solution in 1996. By the building of the accumulation raw water is taken from the river bed of the river Rzav (temporary solution) at the flood dam in Ševelj and by scoop building with mechanical clearing (automatic bar-cleaner) and pump station, is pumped up to the water processing factory. The capacity of this temporary solution is 700 l/s.

* The water processing factory at this stage of construction has capacity of 1200 l/s of pure water. The height plant position ensure gravitational raw water supply from the future accumulation Arilje same as gravitational pure water offtake to the town storage tanks in Arilje, Požega, Lučani and Čačak. Water for Gornji Milanovac is brought by gravity to the pump station located under Gornji Milanovac in the place called Brđani, from where it is pumped to the city storage tanks on the Neškovića Hill.

The map of the pipeline route with objects

The second stage predicts the building of the following objects:

- Water processing factory adding in the part of clearing and filtering up to 2300 l/s capacity.

-The construction of the raw water pipeline as well as main pure water pipelines to the junction to Lučani with the 50% capacity of the final capacity.

Complete investments so far for the water system is 200.757.500 DM

Technological units

The pump station Ševelj

Raw water taken from the small accumulation dam is pumped pumps to the clearing plant. For that purpose it was built the pump station Ševelj at the left bank of the river Rzav downstream from the dam. The pump station is equipped with five pump aggregates with appropriate hydromechanical equipment. Next to the pump station it was built the separate electricity-substation that ensure constant electric current supply.

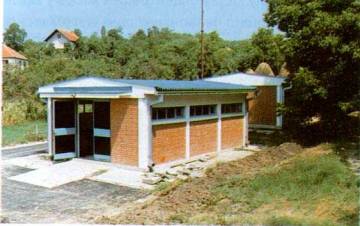

The objects of the pump station and electricity-substation

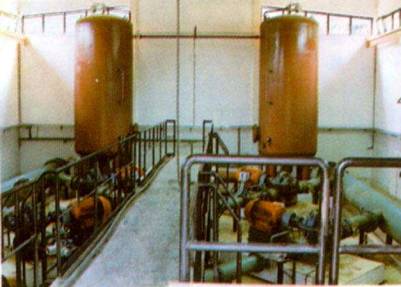

The interior of the pump station

-The raw water cleaning and pure water distribution plant

On the slopes of the hill Klik above Arilje it was built the water clearing factory. Architectonic, technologically and functionally it represents contemporary solution where the latest experiences from the water treatment were used.

The factory solution represents the stage realization. In the first stage the factory of the 1200 l/s capacity is building.

The factory is built by block system. The factory block of buildings includes:

· objects for measuring, regulation and division of the raw water as well as pure water measuring

· contemporary type sedimentation tanks according to the bay-separator principals

· ozonizers

· fast sand filters

· pure water tank

· pump and compression station

· storage and dosing object for chemicals

· commanding-controlling center

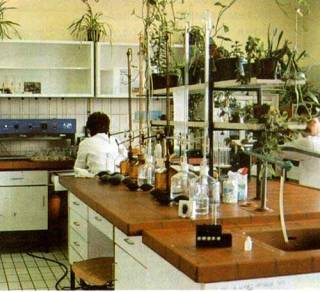

· laboratory

· energetic

· object for waste-water treatment with plants

· administration building

· factory ground arranging with traffic artery and infrastructure

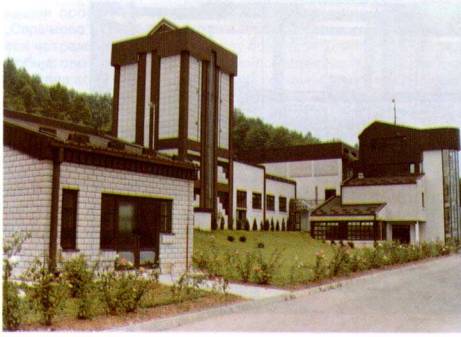

The clearing water factory block of buildings

Technological process

Taking into consideration the water quality of the river Rzav and future accumulation water quality forecast the clearing process includes next:

- adding to raw water

· chlorine for previous chloring for the removing of plankton organisms and bacterias

· sulfuric acid or limestone milk for pH value regulation of the raw water

· active coal in powder for the removing of the colour and smell

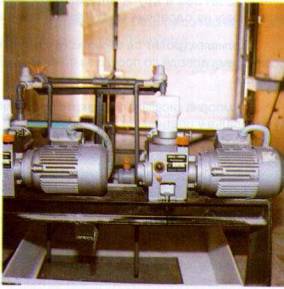

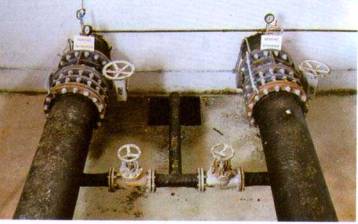

Reciprocating pumps for sulfuric and fluor acids dosing

- clearing up

The clearing up process is consisted of:

· coagulation

· partial mud recycling

· flocullation

· sedimentation

Bay-sedimentation tank

The process of flocullation is done in three stages by slow vertical mixers to whom the number of revolutions can be constantly adjusted. The sedimentation of floculls that formed in flocullators is done in bay-sedimentation tank where the mud is thrown out by the mud shovel.

The mixer’s power is electro-motor via low range lever and motors are equipped with frequent regulators for fine revolutions adjustment.

Ozonizing

After the process, water is taken to chambers for ozonizing. As a very strong oxidation mean in water treatment ozone has following effects: removing of iron, manganese, and colour, smell and organic materials, tears down polycyclic aromatic carbon hydrides and with efficiency react to the removing of micro-organisms and germs.

There are two ozone generators, one is in function, and the other is in reserve.

The process computer manages the ozone generator work with optimal producing conditions reach.

Water ozonizing line

Filtering

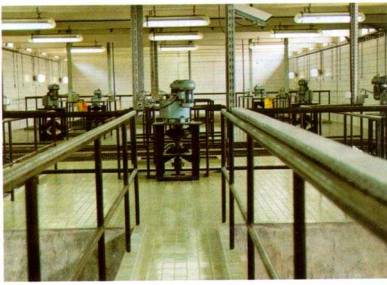

Filter plant is consisted of 8 filter fields with sand filling in. Each filter filled is consisted of two parts separated by the channel for the offtake of the water from washing.

The quality of the filtered water is constantly measured in the dispatcher centre.

Filter plant

Final chloring

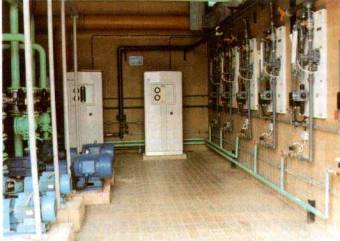

Final chloring is done in pure water tanks and in the pipeline to consumers. Chlorine concentration sent to pipeline is constantly measured and registered in computers in dispatcher centre.

Chloring equipment

Technological waste water

Mud from sedimentation tanks and water from filter washing is taken to the separate plant where the sedimentation of mud from water is done and where the mud is later driven to waste dump. Official bureaus for health protection and its own laboratory constantly observe the state of technological waste water.

Pure water distribution system

Regional water supply system “Rzav” supplies above mentioned 5 cities with water and is responsible for water producing and distribution in quality and capacity till the water entry into the city storage tanks. After that the responsibility is on city communal enterprises that take care of the farther distribution and quality.

-pipelines

The complete length of the pipelines constructed in the water supply system “Rzav” is 76.096 m. The part of the pipeline is constructed for the final capacity.

Concrete pipeline

Steel pipeline

Objects on the pipeline

There are objects built on the pipeline route, where is situated the equipment for the puffing and washing up of the pipeline.

In the cities, objects for measuring and regulation of the flow in local work as well as remote.

Measure-regulation block

Measure-regulation block reinforcing

Managing

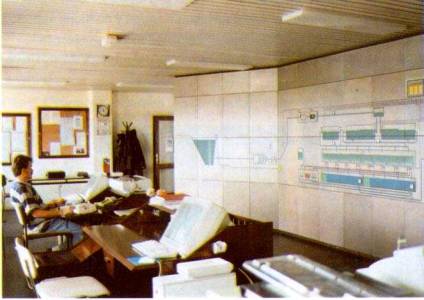

The managing of the technological process and distribution is done from the command-control centre that is situated in the factory in Arilje. The complexity of the technology managing and distribution caused the process control from one place. The control is done by computer equipment supervised by professionals.

There is computer monitoring of the complete system in sense of measuring control and managing as well on process object as in cities users.

Command-control centre

Chemical and microbiology laboratory